T-shirt Printing services comes in many kinds of printing method. Different print methods cater to the different client’s needs, budget and designs. Each printing methods have their own advantages and disadvantages. In today’s article, we will touch the important of heat transfer printing and their power to effectively create a Custom T-shirt.

Heat Transfer Printing Service

Before you embark on doing T-shirt Printing in Singapore, it’s important to understand the various printing techniques available. One of the most popular methods is Heat Transfer Printing, a technique that has been utilized for decades to enhance apparel. This process involves using a heat press machine along with vinyl films to transfer graphics or designs onto the fabric.

Let’s explore the differences between Digital Heat Transfer Printing and Vinyl Heat Transfer Printing, both of which primarily rely on a heat press machine for application.

Vinyl Heat Transfer Printing

Let’s introduce Vinyl Heat Transfer Printing as starters first. Vinyl heat transfers involve the use of single coloured vinyl paper. First, a design is created using a special software. Next, a cutter machine plot and cut out the designs on the vinyl film. Lastly, it has to undergo a manual weeding process. In printing context, weeding means the process of removing excess vinyl films such that the design is ready. It is done manually using special weeding tools or physically with hands. Lastly, the weeded vinyl film is flipped and pressed onto the shirt with the aid of the heat press machine.

Find out more in this video below :

Polyurethane (PU) Heat Transfer: Advantages and Disadvantages

Polyurethane (PU) heat transfer is crafted from 100% polyurethane (TPU) elastic material, offering a unique set of benefits and drawbacks for custom apparel printing.

Advantages

- Cost-Effective for Bulk Orders: PU heat transfer is budget-friendly, particularly for bulk orders of customized names and numbers.

- Affordable for Small Quantities: It is the most economical option for basic customization in smaller quantities.

- Thinner Design: The material is thinner, which can enhance the overall look of the printed design.

- Soft Feel: PU transfers provide a soft texture, making them comfortable to wear.

- Flexibility: The material is flexible, allowing for easy movement without compromising the print.

- Versatile Application: PU can be printed on a variety of materials, expanding its usability across different fabric types.

Disadvantages

- Durability Concerns: Over time, PU prints may peel or degrade, affecting their longevity.

- Washing Recommendations: Hand washing is recommended; machine washing may not be advisable to preserve the print quality.

- Limited Color Range: The color options available for PU heat transfer are somewhat restricted compared to other printing method

Understanding these advantages and disadvantages will help you make an informed decision when considering polyurethane heat transfer for your custom printing needs.

Poly Vinyl Chloride (PVC) Heat Transfer: Advantages and Disadvantages

Poly Vinyl Chloride (PVC) heat transfer is composed of polychlorinated vinyl and polyurethane materials. PVC vinyl films are characterized by their thickness and rigidity, resulting in a more rigid feel on the garment, with finishes that are predominantly matte.

Advantages

- Ideal for Large Designs: PVC is particularly well-suited for large lettering or numbers, making it a popular choice for jersey numbers.

- Cost-Effective: Generally, PVC heat transfer is more affordable compared to other printing methods.

Disadvantages

- Weight Considerations: Large designs can feel heavy on the shirt, potentially affecting comfort.

- Tactile Feel: The printed film can be felt on the surface of the shirt, which may not appeal to all users.

- Washing Recommendations: It is advisable to hand wash PVC-printed garments, as machine washing can compromise the print quality.

- Durability Issues: PVC films tend to be less durable than PU films, with a higher likelihood of wear over time.

- Limited Color Options: The color range available for PVC heat transfer is somewhat restricted compared to other printing techniques.

By understanding these advantages and disadvantages, you can make an informed choice when considering PVC heat transfer for custom T-shirt printing.

TJG Print uses superior PU Vinyl Film. The material is thin which makes it flexible and stretchable. This film is very light-weight, making the print with the shirt feel like one piece. Also, the print does not peel or crack easily when stretched or washed. As a result, the shirt is comfortable to wear. Many Singapore printing companies use PVC Vinyl film which is heavy and less durable. PVC films are thicker which creates a heavy and uncomfortable feeling if one is to print big designs such as jersey numbers.

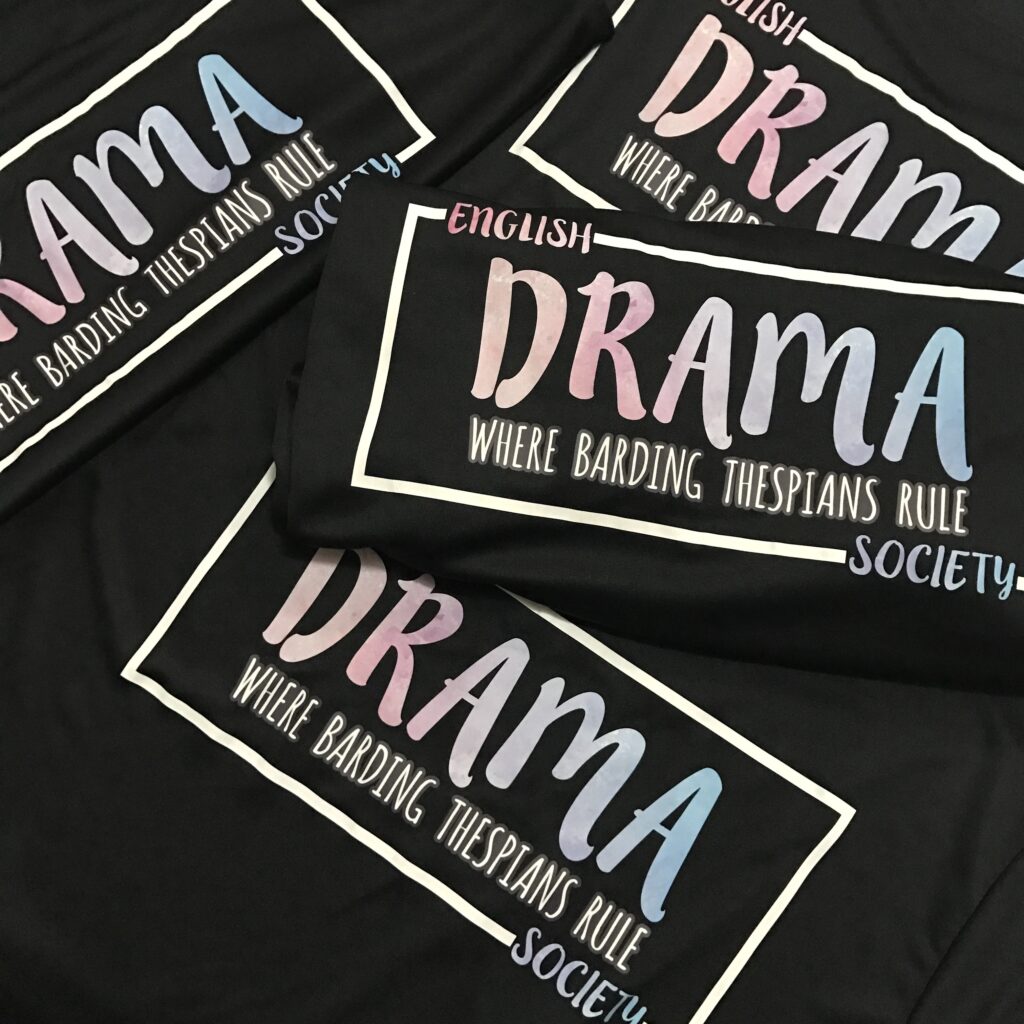

Vinyl heat transfer printing is good for non-complicated designs such as basic shapes, text or numbers. They are available in libraries of colours and one can choose to have a matte or shiny finish. However, one of the restrictions is that vinyl films can only produce a design in one colour at any time. If there is more than one colour, the other colours will have to be printed correspondingly over the other vinyl colour or using digital heat transfer print. A good recommendation of print will be personalised names and numbers on t-shirts and jerseys. This makes it a great choice for sports jerseys as well as class T-shirts

Printing Class T-shirts in Singapore with personalised names and numbers need not be expensive! We have student promotion rates as cheap as $9. Request for quote or chat with us today !

Digital Heat Transfer Printing

Digital heat transfer printing is similar to printing a photograph or full coloured design onto a shirt.

The technique and process is very similar to vinyl heat transfer printing. Firstly, a high resolution and clear design (above 300 dpi) is required for accurate and vibrant coloured finishing. The design is created using software. Secondly, the “print and cut” machine does both jobs of applying coloured ink onto a special heat transfer film and finishes off by cutting out the contour shape of the design. Thirdly, it has to undergo a manual weeding process to remove excess vinyl films.

It is done manually using special weeding tools or physically with hands. Fourthly, a sticky transparent film and a squeegee is required to extract and transfer the printed design over. Lastly, with the stick on film, it is transferred onto the shirt with the aid of the heat press machine. The finishing results are smooth and the bleeding line is almost invisible depending on the shirt and design colour. Dimensions of design and complexity of designs are the cost factor for digital heat transfer. The bigger the design, the more expensive it is. Drop us a message today for a quote!

Recent advancements in printing technology have introduced Direct to Film (DTF) Printing, which offers enhanced durability, flexibility, quality, and a softer feel. This innovative technique combines elements of Direct to Garment (DTG) and traditional heat transfer printing, aiming to phase out older methods such as DTG, screen printing, and conventional vinyl heat transfer.

Digital Heat Transfer Printing: Pros and Cons

Advantages

- Fabric Versatility: Digital Heat Transfer Printing works on nearly all fabric types, unlike Direct to Garment (DTG) printing, which is limited to cotton.

- Streamlined Workflow: The process is straightforward and minimizes mess.

- Soft Finish: The print finish is soft and flexible

- Color Richness: Ideal for designs featuring multiple colors, allowing for vibrant and detailed outputs. Able to do gradient effect designs.

- Precision Detail: Capable of recreating intricate details based on the original artwork.

Disadvantages

- Higher Costs: The cost of digital heat transfer printing remains higher than that of Silkscreen printing, especially for large quantities.

- Less Seamless Finish: The print finish may not be as seamless as that achieved with Sublimation or DTG printing.

- Limited Fading Effects: Printing colours made fade over time

- Workflow: Labour intensive due to peeling and weeding process

- Design Finishing : Bleeding line around designs may not be appealing

As you explore the potential of Digital Heat Transfer Printing, weighing these advantages and disadvantages will help you determine if it meets your specific printing needs.

Durability of Vinyl Heat Transfer & Digital Heat Transfer Printing

With proper care and maintenance, both Vinyl Heat Transfer and Digital Heat Transfer Printing can last between 30 to 50 washes or more. Here are some essential tips to ensure the longevity of your printed shirts:

General Wash Care Tips

- Wash Inside Out: Turn your T-shirt inside out before washing to protect the print.

- Avoid Ironing Over Prints: Do not iron directly on the printed area to prevent damage.

- Use Cool Water: High temperatures can cause prints to peel or crack, so opt for cooler wash settings.

- No Bleach: Avoid bleach, as it can react negatively with vinyl and damage the print.

By following these guidelines, you can help extend the life of your heat transfer prints and keep your garments looking great for longer.

Other than T-Shirts, you can also customize other promotional items available on our catalogue:

More Frequently-Asked-Questions (FAQ) on heat transfer and vinyl printing can be found here.

What Is The Lead Time?

At TJG Print, our lead time for heat transfer printing services is less than 10 working days from the time your order is confirmed. Express printing can be done within 2 days.

What is the Minimum Order?

For Vinyl Heat Transfer Print, no minimum is required. (Basic names & numbers eg. Abc 123)

For Digital Heat Transfer Print, minimum of 10 pieces is required.

What Other T Shirt Printing Services Methods We Offer?

Digital Heat Transfer Print VS Direct To Film DTF Print

Direct To Film DTF Printing is a newly invented printing technology which makes digital heat transfer printing less of a preferred printing choice. Both print methods outcomes are very similar but the “behind the scene” process makes DTF printing look like chicken feet.

The process of Digital Heat Transfer printing can be very tedious and laborious due to the extra weeding and peeling steps. If you watch the digital heat transfer print video we introduced earlier, you will understand the hassle.

DTF Printing skips the weeding and peeling as the inks are directly printed onto the films. DTF Printing is capable of printing intricate designs and small wordings approximately 2mm. Unlike digital heat transfer print, there will be bleeding lines around the design or wordings which may not be so appealing.

However, we cannot rule Digital Heat Transfer printing as a print method out as they are still capable of printing certain products.

Recommendations

Depending on your requirements, for single coloured designs like names and numbers which are often seen at the back of sports jerseys or class t-shirts, we recommend Vinyl heat transfer.

For full multi-coloured images or design, we recommend digital heat transfer. Otherwise, if using lesser colours and larger quantities, a more recommended print will be Silkscreen Printing.

Alternatively, for full customisation, you can consider custom made service with sublimation printing

For further clarifications and enquiries, drop us a message on Whatsapp or email us at sales@tjg.sg.