Printing Methods

Silkscreen Printing

Silkscreen printing is one of the most common printing method. It is the process of transferring ink through the screen and onto the apparel.

Advantages

- Extremely durable and long lasting

- Cost efficient for large quantity

- Wide variety of colours (Able to match pantone colour)

- Able to print small details and wordings

- Can be printed on wide range of apparels and gift products

- Fast turnaround time

Disadvantages

- Expensive for small quantity

- Expensive for multiple coloured designs

- Usually not recommended for gradient effect designs

- Cannot be printed on water-resistant apparels

Understand more about what is silkscreen printing to be equipped with a better knowledge on the best printing method for your designs.

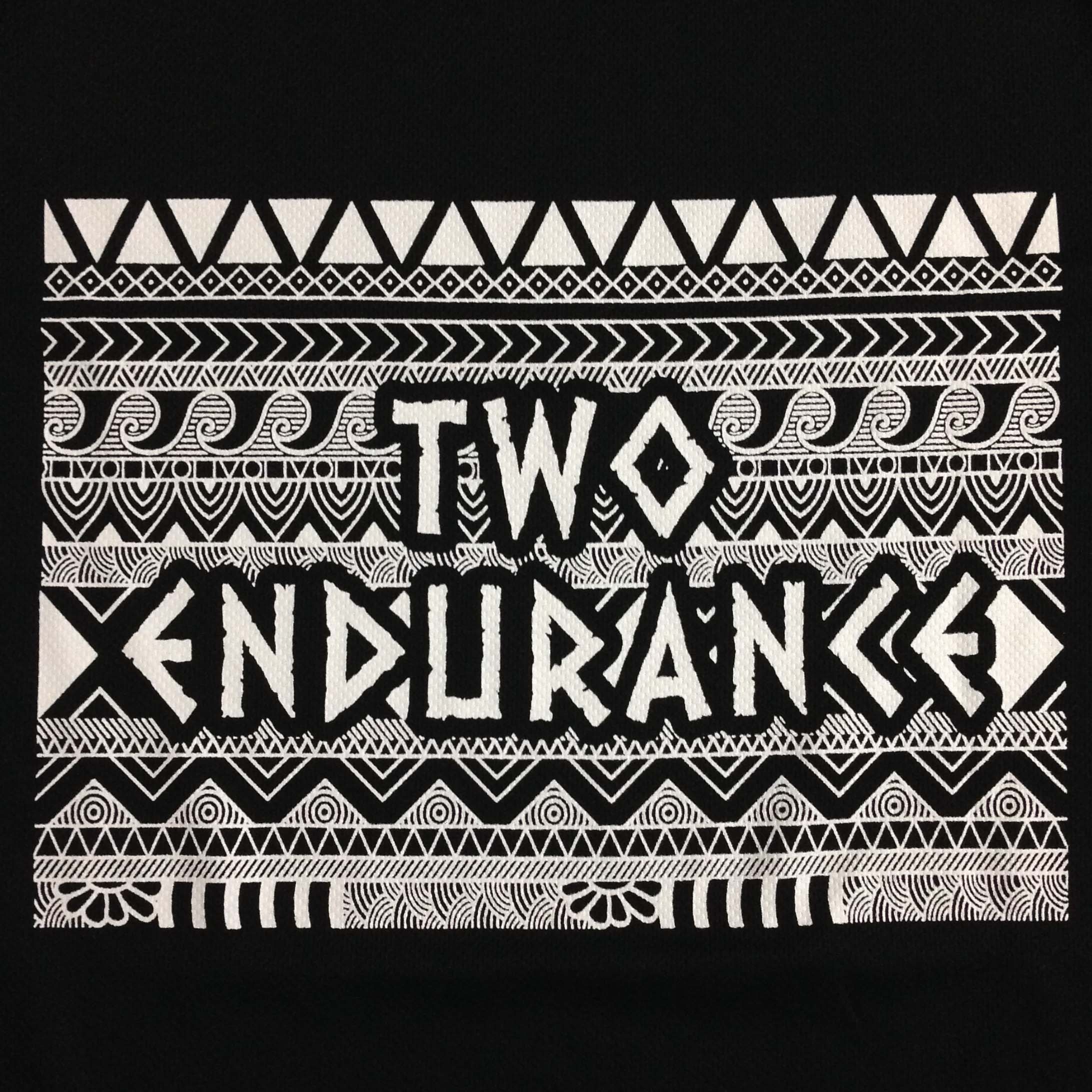

Embroidery

Embroidery is the process of sewing and threading the design onto the apparel. It adds texture which creates a pop-up effect. It provides an impression of quality and professionalism.

Advantages

- Most durable (Does not crack, peel or fade)

- Wide variety of colours

- “3D Pop-up” textured logos make it look professional

- Can be applied on different types of apparels (eg. Caps, Hoodies, Jackets, T-shirts, Polo)

Disadvantages

- Not suitable for small and detailed designs

- Not recommended for large designs

- Have a embroidery backing which may cause itchiness or abrasion

- Unable to achieve gradient effect

- Generally more expensive than silkscreen printing

Understand more about what is embroidery to know when it is best to use this printing method and to learn how embroidery can be achieve on many other products.

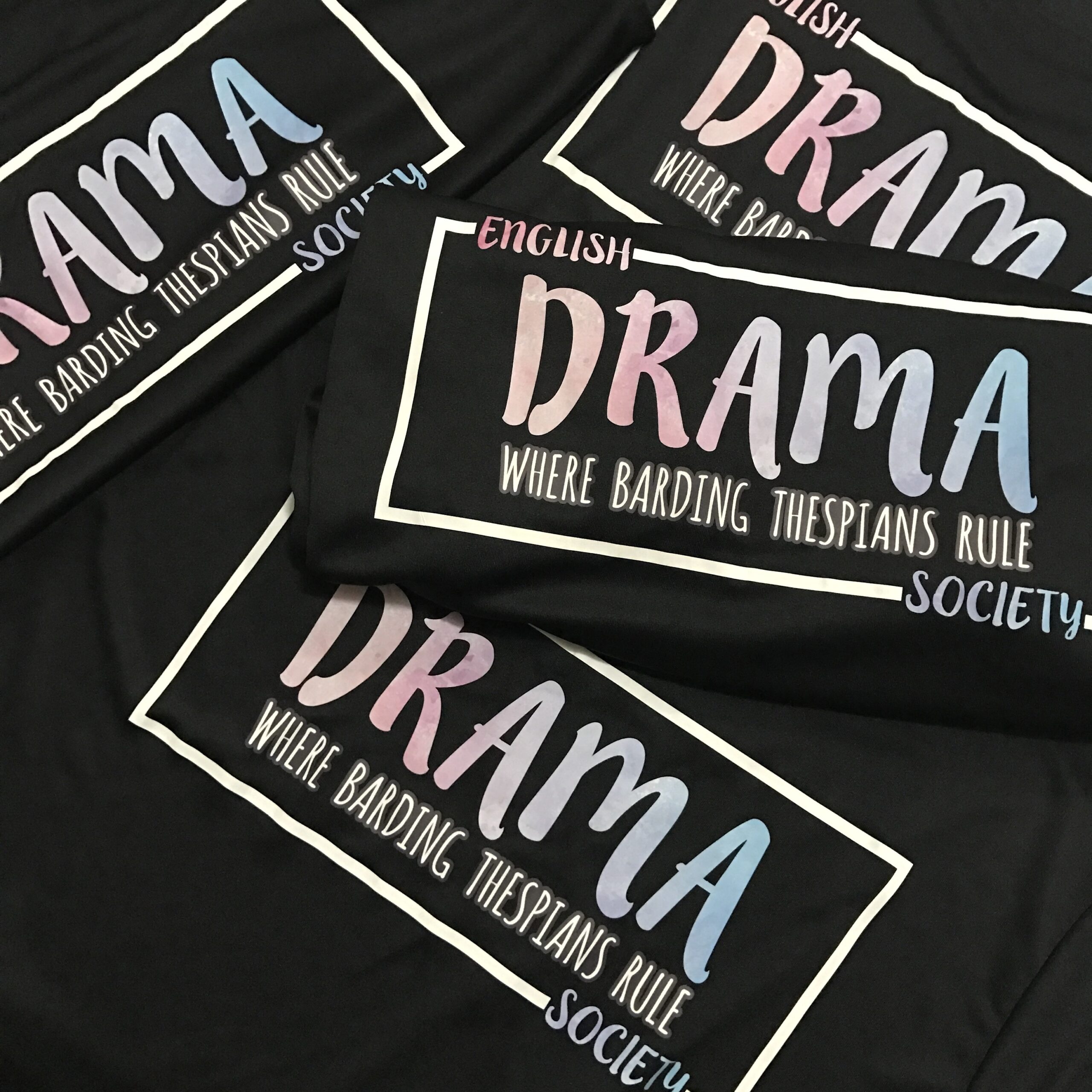

Digital and Vinyl Heat Transfer Printing

Digital & Vinyl Heat Transfer Printing is the process of using a film and transferring it onto the apparel via intense heat. As such, the films are glued onto the T-shirts or gift items.

Digital Heat Transfer printing has the ability to do multi-coloured designs and even gradient designs.

Vinyl Heat Transfer printing are solid 1 colour films which are usually use for custom names & numbers. It is common among Class T-shirts and Sports Team Jersey (Eg. Soccer, Basketball and more). At TJG Print, we use high quality PU film material instead of PVC film material. PU Films are softer, more flexible and more durable.

Digital Heat Transfer Printing

Advantages

- Cost friendly for smaller quantity with coloured designs

- Able to achieve gradient effect

- Able to achieve multi-coloured designs

- Versatile and can be printed on many types of apparels and gift products

Disadvantages

- Not very durable (May peel or crack in the long run)

- Must have a bleeding line background

- Colours may fade away with time

- Recommended to hand wash. Not suitable to be placed in dryer

Vinyl Heat Transfer Printing

Advantages

- Cheapest form of customisation (Eg. Names & Numbers)

- Fast and quick turnaround printing method

- Can be printed on a wide range of apparels and gift products

Disadvantages

- Not very durable (May peel or crack in the long run)

- Recommended to hand wash. Not suitable to be placed in dryer

- Limited colour range

Understand more about what is heat transfer printing service and know more about the difference between digital heat transfer print and vinyl heat transfer print. While this printing method is considered more traditional than DTF printing, it still remains a useful and viable printing method to date.

Dye Sublimation Printing

Dye sublimation is the process of binding dye ink with the fabric such that it is one homogeneous material. The designs are embedded into the fabric itself.

The sky is your limit, sublimation print allows any customization of design and we can custom build it from scratch into Singlet, Short Sleeve, Long Sleeve, Polo Collar, Raglan, Oversize and more.

Advantages

- Prints are permanent, it will not fade or peel off

- Able to achieve multi-coloured designs and gradient effects

- No irritation caused by prints as the prints are bonded into the fabric itself

- Able to customise in different cutting styles and apparel types

Disadvantages

- Can only be printed on polyester material

- Generally pricing are on the steep side

- Longer turnaround time

Understand more about what is sublimation printing and know how you can achieve and churn out the best custom sublimation T-shirts.

DTF Printing (Direct to Film)

DTF Printing is one of the latest printing technology which was invented in the late 2010s. It is the process of digital inks printed directly onto the films which undergoes a powdering process. The cured and ready films are transferred onto the apparels or gift products through heat press machine. It skips out the tedious weeding process by the conventional digital and vinyl heat transfer printing method.

Advantages

- Cost friendly for multi-coloured designs in small quantity

- Able to achieve gradient effects

- Much more durable than digital heat transfer printed films

- Great for intricate and small designs

- Faster turnaround time

Disadvantages

- Not very durable (May peel or crack in the long run)

- Recommended for hand wash. Not suitable to be placed in dryer

- Colours may fade in the long run

Understand more about what is DTF Printing and how it revolutonize the printing industry by creating a smoother printing process.